Rout |

Clean |

Seal |

| Spring season is an ideal time to crack seal because pavement cracks are at their mid-point and temperatures are moderate. Studies by the National Center for Asphalt Technology found that crack sealing is proven to extend pavement service life in all conditions (good, fair and poor). |

First, let’s understand what causes the pavement to crack and what treatment options are available.

Cracks are inevitable, and neglect leads to accelerated cracking and potholing, further reducing pavement serviceability according to FHWA.1

Asphalt pavement is exposed to sunlight, ultraviolet rays that oxidize the surface, causing the pavement to become brittle. Asphalt pavement is always moving either horizontally due to changes in temperature or vertically due to traffic loads. As the pavement becomes brittle and is subject to movement it cracks. The crack is then exposed to infiltration of water, impurities, debris that accelerate the damage. Cracks can become visible within the first year after a newly paved road, and 75% of unsealed cracks can turn into potholes within 3 years.

Now that you know what causes the pavement to crack, let’s look at the two treatment methods to repair cracks. You can use crack sealant or crack filler.

Crack sealant is (1) specialized materials that bond to the walls of the crack and can move horizontally and vertically with the pavement as it expands and contracts; (2) prevents intrusion of water and debris into the crack; and (3) is specifically engineered to remain flexible at low temperatures so it does not crack or split open and remains stable at higher temperatures so that it does not track or bleed on the pavement. Examples of crack sealant are Crafco Roadsaver, Polyflex and Asphalt Rubber hot-applied sealants.

Crack filler is (1) ordinary materials that do not bond well to the crack and is not able to move with the pavement as it expands and contracts; (2) reduces intrusion of water and debris into the crack; and (3) is not specifically engineered to remain flexible at low temperatures and may not remain stable at higher temperatures. When pavement movement takes place due to temperature change or traffic loads, the crack filler is separated from the edge allowing water and incompressible materials to enter the crack and into the pavement. Examples of crack filler are oil and sand, asphalt cements, liquid asphalt, cutback asphalts, or asphalt emulsions.

As you can see from the definitions, there are differences in the materials that are designed for different purposes – prevention vs reduction of infiltration is a significant difference.

Crafco has the industry-leading crack sealing tools to help you get the most out of your efforts.

1. Crack sealing is the proven, lowest-cost-with-highest-benefit pavement preservation treatment!

For the majority of cracks that develop in pavement, the best treatment is crack sealing. Unlike crack filling, which usually only lasts one to two seasons, crack sealing can seal, protect, and preserve the pavement for more than seven years, and has proven to extend pavement service life more than 7 years.

Why choose Crafco sealants? Crafco achieved the longest pavement sealant service life in the industry! – Cracks sealed using Crafco high-quality sealants have been proven to extend sealant service life for more than 7 years in Asphalt Cement (AC) and 21 years in Portland Cement Concrete (PCC) pavements.*

*Data on file

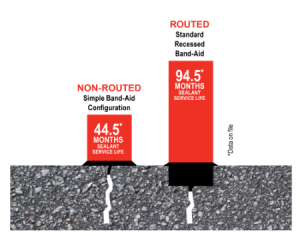

2. Double sealant service life by routing

When performed prior to use of Crafco’s high-quality sealants, routing provides a solution proven to double sealant service life vs. non-routed and sealed cracks — making the most of your investment. Our rout/seal configuration has resulted in sealant service performance in asphalt pavement for 7+ years — the longest in the industry.

Why use the Crafco Pavement Router? Our router has been the industry standard for more than 30 years. There is no better way to effectively and efficiently create sealant crack reservoirs than with the Crafco Model 30 Pavement Router. Its lightweight mobile design, unique center of balance, and cutter-head alignment make it easy to operate and deliver unsurpassed crack-following accuracy. Routing cracks will prolong pavement life, will prolong sealant life, and prevent potholes.

3. Clean Routed Cracks for longer sealant performance

Independent studies prove that clean, dry pavement cracks treated with a routed reservoir extend sealant’s performance (achieving 7+ years in SHRP H-106). This longer lifespan not only limits sealant costs but eliminates labor, materials, road closures, traffic control/congestion, and driving hazards associated with rework.

Cleaning cracks has never been easier or more effective than with the new Crack-Vac 2!

Why choose the Crafco Crack-Vac 2? Our Crack-Vac 2 is uniquely designed to be the most effective at cleaning cracks or patching potholes. It removes dirt and debris from pavement cracks, virtually dust-free, with compressed air, ensuring proper preparation. The Crafco Crack-Vac 2 reduces respirable dust and silica exposure, achieving the industry’s lowest OELs.

Contact us to learn more about our industry-leading crack sealing equipment and materials

"*" indicates required fields